Engineering

Power, un-leashed.

Creating cutting-edge technology demands unconventional thinking. Which is how motorbike parts and fishing rods helped with developing the digital motor that powers our Dyson V7™ vacuum.

"No-one was designing the type of motor we needed. So we spent eight years developing our own. Without it, our cord-free vacuums could not deliver such power. "

James Dyson

Inventor

Opening the throttle.

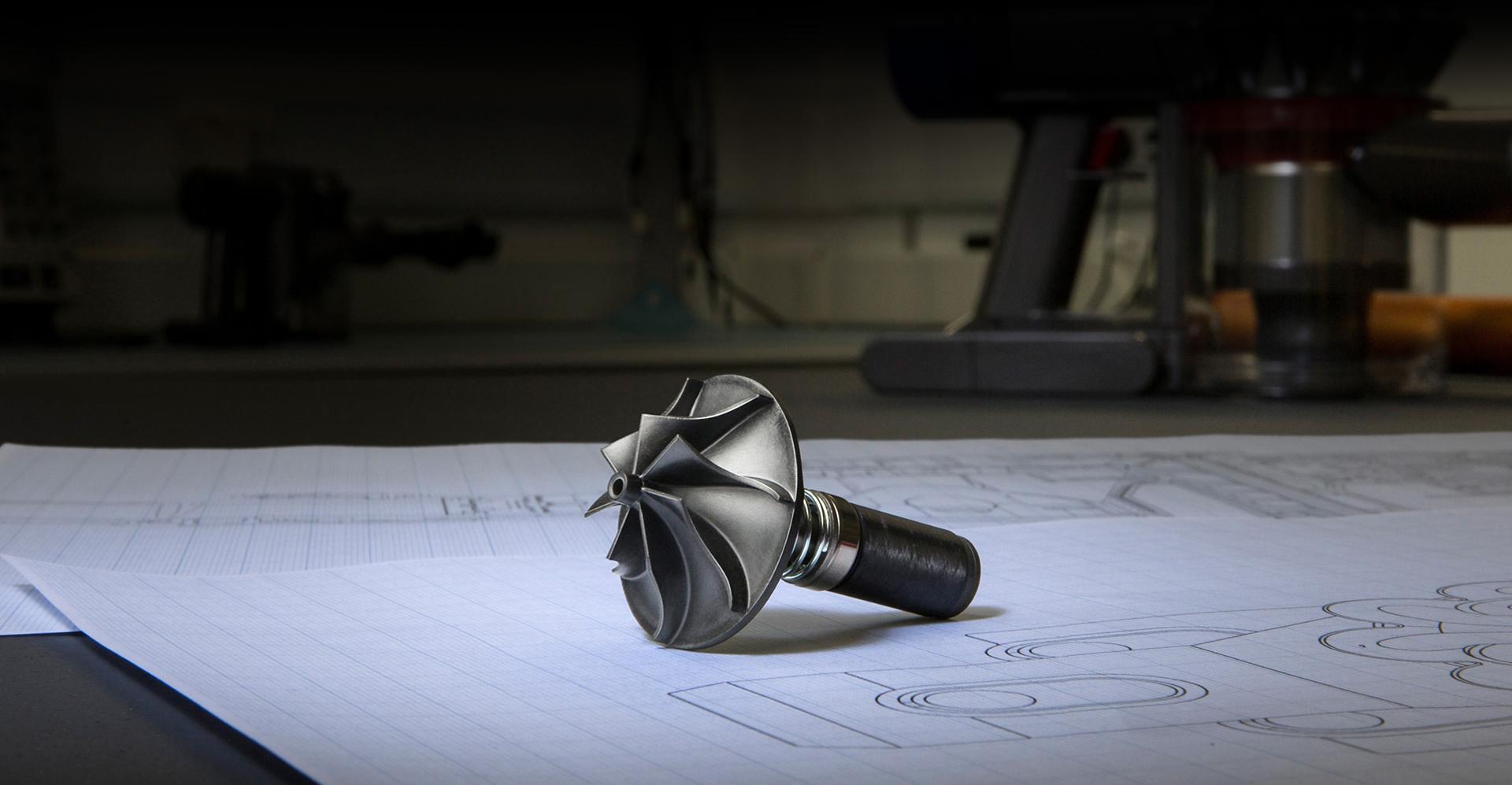

In 1997, conventional motors were still using 160-year-old technology. So we started developing smaller, faster digital motors – by adding intelligent software to a motorbike impeller.

Digital revolution.

By 2009, we'd created the 200W Dyson digital motor V2. Small and light, it span at 78,000rpm, providing the power we needed for our first cord-free stick vacuum.

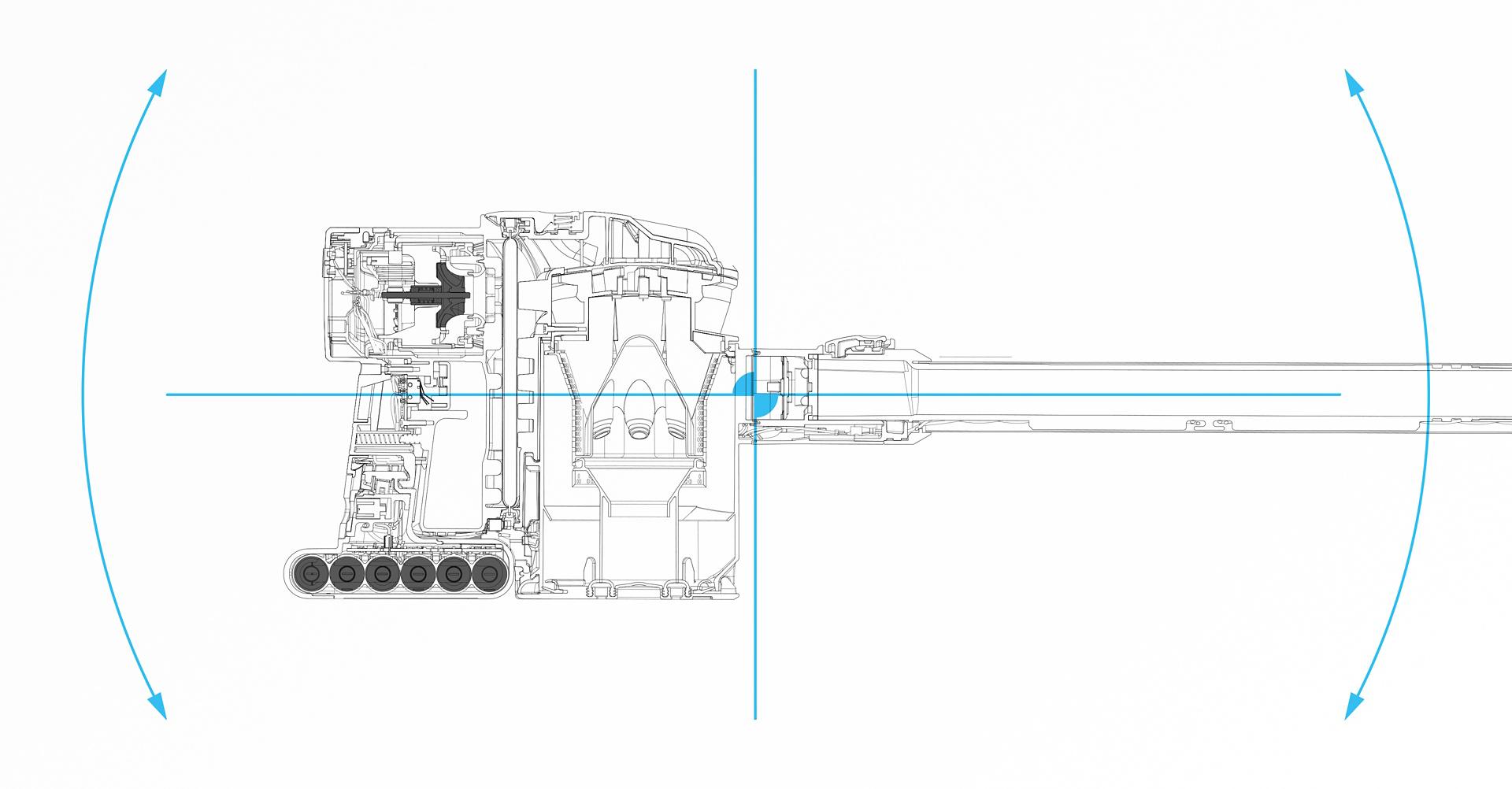

Ergonomic efficiency.

The Dyson Digital Slim™ vacuum launched in 2011. With the motor and the battery in the handle, it had the optimum centre of gravity for floor-to-ceiling cleaning – and created a new kind of vacuum cleaner.

Pushing the boundaries.

As our engineers developed our next-generation 350W Dyson digital motor, we had to find a casing robust enough to hold the motor together while it span at 110,000rpm.

Racing ahead.

So we investigated the super-strong, ultra-light casing used in Formula 1 for its KERS flywheel technology. And then we created our own – by adapting carbon fibre fishing rod tubes.

Powered up.

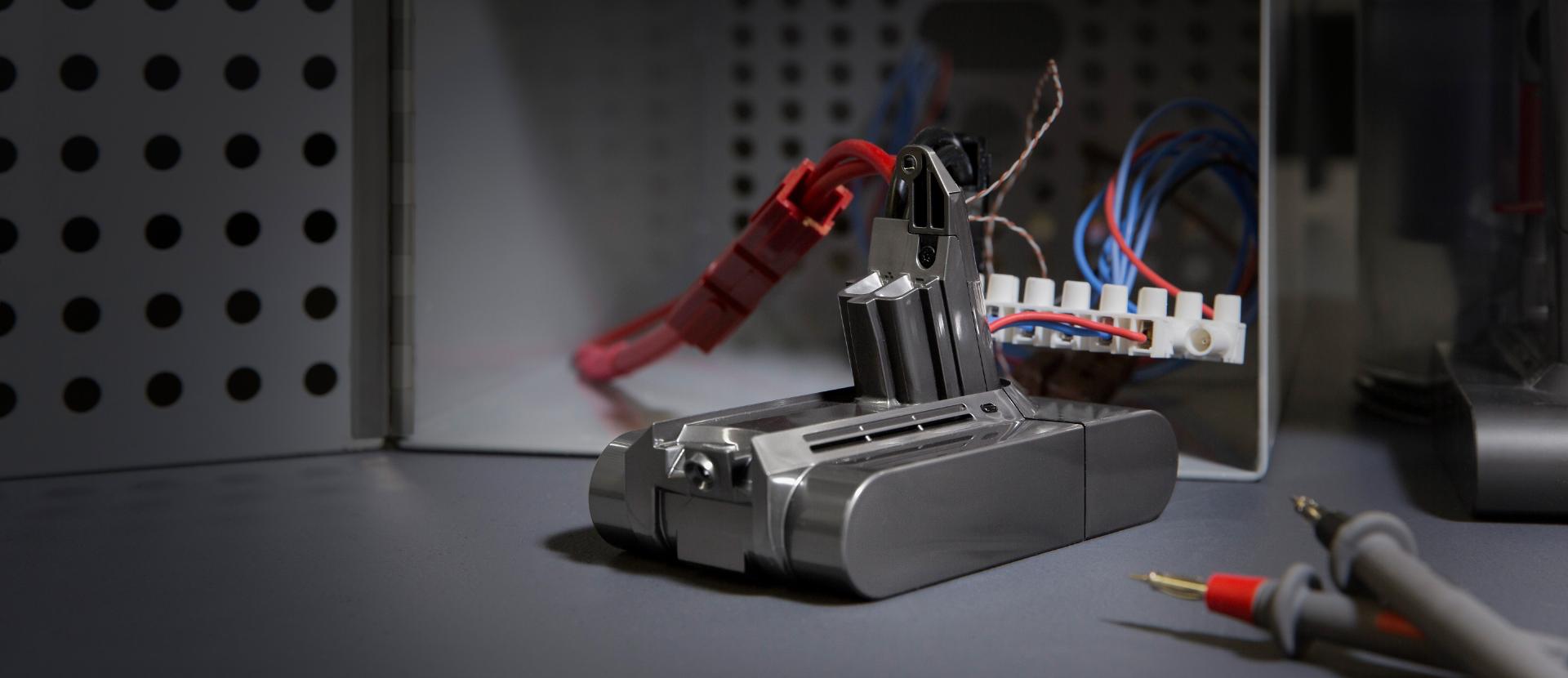

In 2014, our new motor powered the Dyson V6™ stick vacuum. With a redesigned nickel manganese cobalt battery, it had 150% more power than its predecessor, and a run time of up to 20 minutes.*

Increased performance.

But we didn’t stop there. We retuned the battery to increase the run time of the Dyson V7™ vacuum to 30 minutes*, and cut noise with improved acoustics.

- 320 Patents on Dyson V7™ cord-free vacuums

- 150 Dyson engineers worked to improve the motor

- 290 Miles pushed during testing

1Up to 20 minutes with motorised floor tool attached. Up to 6 minutes in MAX mode.